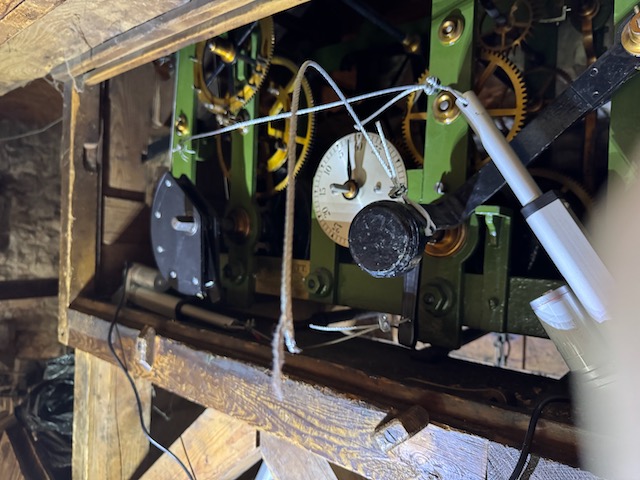

About three months ago, I wrote about replacing a snapped galvanised steel wire rope on a clock winder. Unfortunately, it has snapped again!

I am very surprised that the steel wire rope snaps, as the weight it lifts is, at most, 2 kg, however it does run every hour. I posed the question to Claude:

Hi Claude, I have a mechanism which lifts a 2Kg weight using a multistranded galvanised steel wire rope with a diameter of 3mm over a 20mm diameter pulley. It works fine, but the rope snaps after about 3 months of operating once per hour. Can you suggest where the issue might lie?

“The most likely issue is your pulley diameter is too small relative to your wire rope diameter. With a 3mm rope over a 20mm pulley, you have a diameter ratio of only 6.7:1, which is well below recommended standards.

Key problems with small pulley diameters:

- Excessive bending stress in the wire rope as it wraps around the pulley

- Rapid fatigue failure from repeated flexing (your ~2,160 cycles over 3 months)

- Individual wires break from the severe bending, leading to rope failure

Industry recommendations:

- Minimum D/d ratio should typically be 20:1 for standard applications

- For your 3mm rope, you’d ideally want at least a 60mm diameter pulley

- Higher ratios (30:1 or more) would be even better for longevity”

With this insight, I was easily able to verify that this is a good assessment. For example, Flints recommend, “In the case of wire ropes, the sheave diameter should ideally be 30 times the diameter of the wire.”